Constructed Wetlands for swine wasterwater

Livestock - IRIDRA's solutions

Classical constructed wetlands

- Constructed wetlands with horizontal subsurface flow (HF)

- Constructed wetlands with vertical subsurface flow (VF)

- Constructed wetlands with free water surface (FWS)

- Hybrid constructed wetlands (HF + VF, VF + HF, HF + VF + FWS, HF + FWS, HF + VF + HF + FWS)

Intensified constructed wetlands (Constructed wetlands 2.0)

- French reed bed (FRB)

- Aerated constructed wetlands (FBA™)

Additional integrated solutions

- Sludge drying reed bed (SDRB)

Additional integrated solutions in the field of circular economy

- Coupling with anaerobic digestor for biogas production

- Coupling with reactors for fertilizer production (stripping, struvite)

Current laws concerning water protection from pollution due to wastewater, represented in Italy by the law n. 152 of 11 may 1999 and its integrative law n. 258 of 18 August 2000, have individuated two typologies of wastewater: civil wastewater produced by urban areas or similar, and industrial wastewater. Inside of this typology, particularly important is wastewater produced by productive centres like cheese factories, dairy and swine industries. All these activities produce wastewater that is so polluted that particular attention is necessary for the individuation of the most adequate approach for a correct depuration.

Wastewater of a cheese factory, for example, contain high concentrations of solids, grease and nitrogen and phosphorus compounds; these substances can result in eutrophication of downstream water bodies, damaging and altering aquatic ecosystems. It has been observed that this kind of wastewater present average values of BOD5 ranging from 1500 to 8000 mg/l, that is 30 times the concentration of typical civil wastewater. Swine industry produces wastewater characterized essentially by blood, faeces, urinals, stomach content, and other various residuals of washing water of working rooms and machinery; moreover, there is a strong presence of solid materials constituted by residuals of furs, rush, food and many greasy substances. For this kind of activity, it has been observed wastewater with average values of BOD5 ranging from 2500 to 3000 mg/l, that is 10 times the concentration of typical civil wastewater.

Another important characteristic that matter with depuration of wastewater of zootechnic industry is represented by the fact that the working activity is seasonal, for it is connected to productive period of animals, and that the operations are limited to a part of the day, generally 8-12 hours, and don't take place every day of the week. The characteristics of the wastewater, therefore, tend to vary in its quantity and quality following productive phases. Principal problems connected to the production of wastewater of zootechnic industry are the presence of pathogens, odours, high concentrations of nutrients and lack of adequate on-site treatments.

The traditional method of waste management used for a century in the zootechnic industry is the waste application to land: it is the primary source for cropland fertilization, but it has problems as high solids content, high nutrient concentrations, limited pumping distances. Alternatively, in the biggest activities, it is possible to find technological plants for wastewater treatment.

Constructed wetland for swine wastewater

Constructed wetlands compared to conventional systems have less construction, operation and energy costs plus more flexibility in pollutant loading. It has been showed that constructed wetlands significantly reduce concentrations of nutrients, solids, and oxygen-demanding substances in zootechnic wastewater. It has to be noted that a good solid removal prior wetland treatment it is necessary to assure a long term functionality.

It is interesting to observe that, in case of productive activities situated in isolated places not connected to the net, the utilization of constructed wetland systems represent an optimal solution also for the treatment of wastewater produced by residential houses present in the factory.

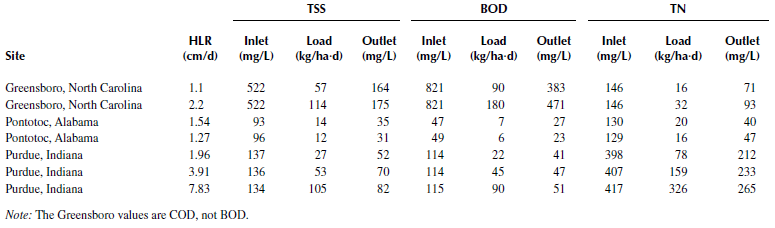

The use of nature-based solutions for swine wastewater started in 90s, especially with extensive solutions such as anaerobic lagoons followed by free water surface (FWS) systems, showing good removal of BOD, TSS, and total nitrogen. Great experience of these solutions come from the USA, where the LWDB (Livestock Wastewater Database) censed 135 applications. More efficient constructed wetland (CW) solutions were also tested, such as conventional horizontal and vertical flow systems (Kadlec and Wallace, 2009).

Removal efficiencies of FWS treating swine wastewater. Kadlec and Wallace (2009).

In order to reduce the areal footprint, the combination with the anaerobic reactor (Liu et al., 2015) and use of intensified constructed wetlands (Wu et al., 2014) have been recently investigated. An example is the pilot plant monitored by Wu et al., (2015), where was tested the combination of an anaerobic reactor with an aerated wetland; the pilot plant has shown good removal efficiencies in terms of organic load (52–72% removal of COD) and very high removal of ammonia (>98%).

IRIDRA's experience

IRIDRA has designed, installed, and monitored the pilot plant of Magnacallo (MN - Italy) of S.A.S.A. Srl, in collaboration with Reinnova Srl and financed by ENAMA. The pilot plant consists of a UASB reactor followed by a series of wetland systems, including aerated wetlands. Despite very high pollutant loads, the pilot plant performed well in terms of TSS, COD, N-NH4+ and TKN (99.9%, 99.6%, 99.5%, e 99.0% on mean values, respectively).

On the basis of the pilot plant experience, IRIDRA, in collaboration with GWT, has designed one of the first full scale aerated wetland system for swine wastewater treatment, the one sited in San Rocco di Piegara (Roverè Veronese - VR - Italy). The CW plant treats the swine wastewater produced by up to 3000 pigs (38 m3/d).

Aerated wetland pilot plant for treatment of the swine wastewater from a pig farm in Magnacavallo (MN - Italy) of S.A.S.A. Srl., designed and monitored by IRIDRA, installed by Reinnova Srl and financed by ENAMA

Aerated CW WWTP of San Rocco di Piegara pig farm (Roverè Veronese - VR - Italy), designed by IRIDRA.

Pig farm S.A.S.A. S.r.l., Roveré Veronese (VR - Italy)

Livestock: 3000 pigs

Chosen Nature-based solution: FBA™ + lagoon

Peculiarity: First aerated treatment wetland for swine wastewater in Italy and among the first worldwide

Year of design: 2016

The treatment plant was designed by IRIDRA in collaboration with Rietland Agro (ing. Dion Van Oirschot) and NaturallyWallace (ing. Scott Wallace) and is under construction.

The CW treatment plant uses the FBA™ (Forced Bed Aeration™) technology to aerate the beds, increasing the treatment efficiencies and reducing the requested area.

The CW treatment plant is designed to treat the swine wastewater produced by up to 3000 pigs (38 m3/d).

It is one of the case studies of the Joint Research Centre project "Nature-based solutions for climate change adaptation and water pollution in agricultural regions", representing the use of NBS for treatment of manure in continental environment (LOT 2). The JRC study is headed by IRIDRA SRL in collaboration with Alessandro De Carli (economic analyses) and ARCO - Action Research for Co-Development (social analyses).

Pig farm of S.A.S.A. S.r.l., Magnacavallo (MN - Italy)

Livestock: 1500 sows

Treated wastewater quantity: 1 m3/day (pilot plant)

Chosen technological plus Nature-based solution: UASB + FBA™ + FBA™ + HF

Year of realization: 2015