Constructed Wetlands for landfill leachate

Nature-based solutions are a valid alternative for the treatment of landfill leachate. Constructed wetlands started to be use for landfill leachate treatment since the 80s, testing both horizontal subsurface flow and free water surface systems. Nowadays, the most common solution for leachate treatment adopts multistage hybrid systems downstream an equalization tank, which is usually requested to collect the variable landfill produced in function of rain events.

Landfill leachates - IRIDRA's solutions

Classical constructed wetlands

- Constructed wetlands with horizontal subsurface flow (HF)

- Constructed wetlands with vertical subsurface flow (VF)

- Constructed wetlands with free water surface (FWS)

- Hybrid constructed wetlands (VF + HF, VF + VF + HF + HF + FWS)

Intensified constructed wetlands (Constructed wetlands 2.0)

- Aerated constructed wetlands (FBA™)

Integrated low-tech solutions

- Lagoons

Removal efficiencies

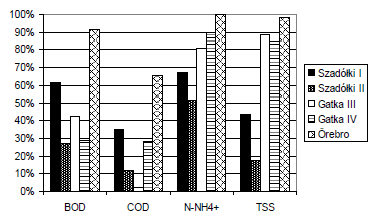

Constructed wetlands for landfill leachate treatment show good removal efficiencies, which can vary according to different sizes, hydraulic regimes, and primary treatments (Wojciechowska et a., 2010).

Average removal efficiencies from different Polish and Sweden case studies. (Wojciechowska et a., 2010)

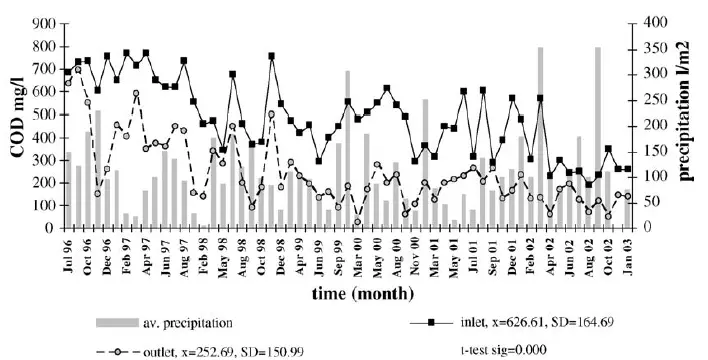

A good design guarantees high removal efficiencies. For instance, mean removal efficiencies registered from 7 Slovenian case studies were: BOD5 68%, COD 73%, N-NH3+ 75%, TP 73%. The CW WWTP treating the leachate from the landfill of Chunchulala in Mobile County (Alabama – USA) has shown the following average performances: TSS 97%, COD 90%, TOC 87%. The landfill of Laflèche, Eastern Ontario, treats the landfill with a CW WWTP which was monitored the first two years of operations, showing high mean removal of organic load (95%) and ammonia (99%). Satisfactory organic removal were observed also in cold climates; for instance, the CW treating the leachate from the landfill of the Municipality of Kodiak Island, in Alaska, had mean removal of 40% for COD and 36% for ammonia, high metal removal (99% for Fe and 44% for Mn), and a clear effluent. Good performances were observed also in long term monitoring, as shown by Bulc (2006), which monitored a landfill leachate treatment plant for 7 years, reporting constant removal efficiencies of 50% for COD, 59% for BOD5 and 51% for ammonia.

Influent and effluent COD concentration correlated with precipitation for 7 years of monitoring of a CW for landfill leachate. Bulc (2006)

Constructed wetlands coupled with Sequencing Batch Reactors (SBRs).

The combination of SBR and CW is one of the most promising options of integration between nature-based and technological solution for wastewater treatment (Liu et al., 2015). SBR+CW scheme was often adopted in the UK for leachate treatment. Indeed, about 80 treatment plant for with SBR+CW scheme is reported (Mulamoottil et al., 1999). One example is the landfill of Judkins Quarry (UK), reported in the following picture.

Areal view of the SBR+CW plant for treatment of leachate from the Judkins Quarry landfill (UK).

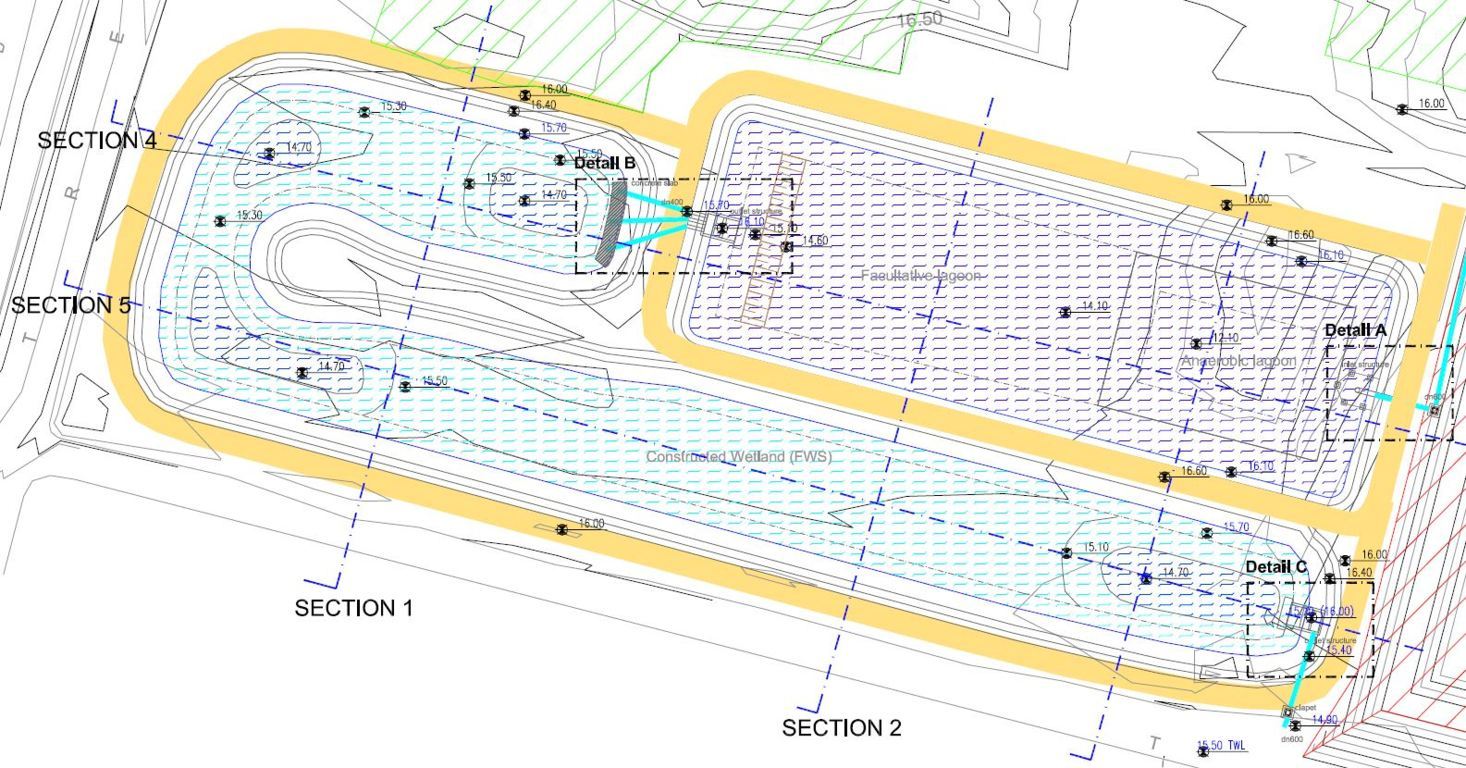

Perseverance landfill, Grenada

Design flow: 100-110 m3/d

Chosen Nature-based solution: HF + FWS

Peculiarity: treatment of landfill leachate located in a very environmentally sensitive area

Year of realization: 2018

This project regards the detailed design of a wastewater treatment plant for the leachate produced by the Perseverance Landfill in Grenada. The Perseverance landfill is in a very sensitive area from an environmental point of view. The landfill leachate is discharged within the Salle river, which flows into a mangrove swamp and in a narrow bay closed by the reef after few hundred meters. For these reason, the capping of the existing landfills, the extraction and the treatment of the produced leachate are mandatory to ensure a sufficient environmental protection of the area, not threatening the touristic and the local use of the area.

The adopted option to sustainably manage the leachate of the Perseverance Landfill has been chosen in accordance with Grenada Solid Waste Management Authority, considering the available area, the need of a practical solution (easy to operate and to maintain), and the available material on the island. This option adapts an already tested and feasible approach diffused in Slovenia and in other countries to the local context, providing the combination of Treatment Wetland, Phytocapping and Phytoremediation technologies.

Taglietto landfill, Villadose (RO - Italy)

Treated person equivalent: 338 PE (referred to organic load)

Chosen Nature-based solution: VF + VF + VF + HF + HF + FWS

Peculiarity: First constructed wetland for landfill leachate in Italy

Year of realization: 2010

San Donato landfill, Vinci (FI - Italy)

Treated wastewater quantity: 8.5 m3/day

Chosen Nature-based solution: VF + VF + VF + HF + HF + FWS

Year of design: 2010

Lusignan landfill (Guyana)

Treated wastewater quantity: 100 m3/day

Chosen Nature-based solution: Lagoon + FWS

Year of design: 2014

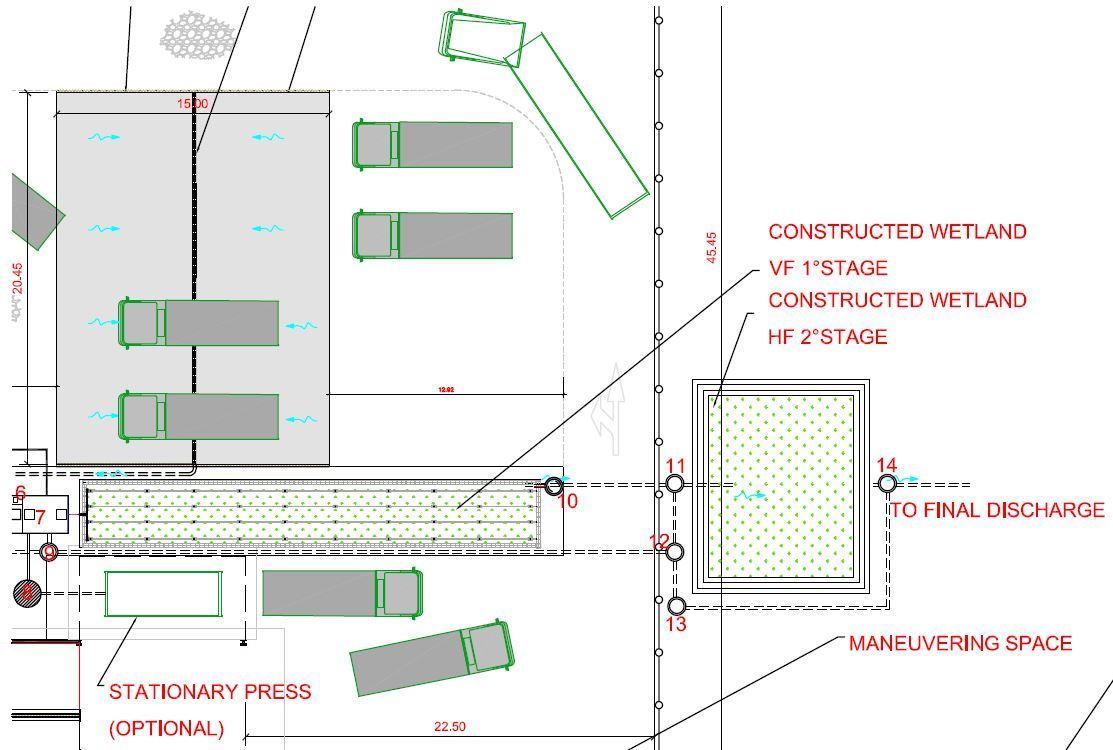

Transfer station for touristic areas (Belize)

Treated wastewater quantity: 4.9 - 5.2 m3/day

Chosen Nature-based solution: VF + HF

Peculiarity: Treatment of landfill from waste compaction in transfer stations

Year of design: 2016

Treatment plant for not dangerous wastes of Belvedere S.p.A., Peccioli (PI - Italy)

Treated wastewater quantity: 1 m3/giorno (pilot plant)

Chosen Nature-based solution: HF

Peculiarity: Trattament of water from evaporation tower

Year of realization: 2014